All Dantherm residential ventilation units fulfil the market’s high demands for low energy consumption and

noise levels. Demand control combined with low-noise EC fan motor technology ensures high energy efficiency and contributes to low SFP (Specific Fan Power) values.

In an MVHR unit, the rate of air change is normally approx. 0.5 times per hour. However, Dantherm residential ventilation units can provide a cooling effect in the warm season by means of bypass dampers or bypass shunts.

The HCV 300-400-460-500-700 residential ventilation units are primarily designed for villas and apartments. They meet ventilation requirements of houses up to 450m2 or more, depending on national requirements and the actual

pressure loss in the installation.

The units are supplied as packaged basic ventilation units complete with a built-in control panel and are delivered

with all parts necessary for wall installation. A wide range of additional accessories are available.

The residential ventilation units are fitted with highly efficient counter-flow heat exchangers, which are optimised to a high-efficiency level, thus achieving a low power consumption (SPI value) for the entire unit.

All units are equipped with easy-access filter slots behind the upper front cover. The control panel with LED light indicators is located in an opening in the front cover.

The HCV insulation is made of expanded polystyrene (EPS) components with a minimum wall thickness of 32mm. This allows the units to be placed in rooms with temperatures as low as +12°C.

The outer surface is made of 0.8mm Aluzinc powder-coated sheet metal and painted in RAL 9016. The HCV series complies with European fire safety requirements as specified in EN 13501 class E.

The leakage rate of the unit (internal and external) is <2% as specified in EN13141-7 leakage class A1.

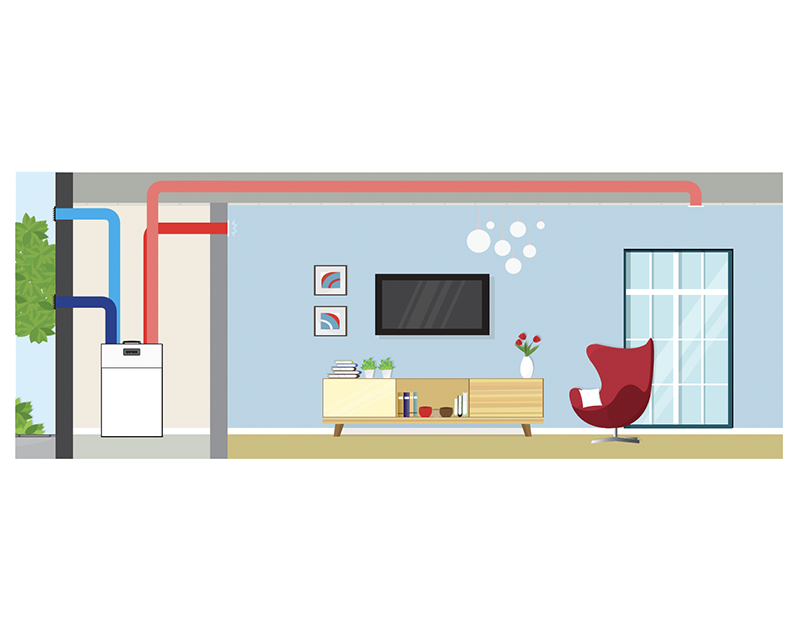

The unit ventilates residential homes by extracting the inside humid air, and replacing it with fresh outside air, which has been heated with the heat energy of the extracted air. This reduces energy consumption.

The air volume can be controlled by:

Selecting a fixed fan speed from 0-4

Demand mode, in which a built in RH sensor continuously

adjusts the fan speed depending on any immediate demand,

determined by the humidity of the extracted air

Week timer program – the fan speed will increase or decrease

according to an hourly time schedule, or specific demand

When very humid inside air is extracted, the humidity will condensate

inside the heat exchanger and be collected by the embedded drip

tray. This water is drained from the unit through the enclosed hose

and then disposed of in the nearest drainage.